In the automated sample preparation of PFAS analysis, the Freestyle SPE instrument system

from LCTech in the PFAS version in combination with the vacuum concentrator D-EVA allows specially adapted

automated concentration of the substances.

Now, the analytical methods for the determination of PFAS are far from being as harmonized and regulated as for other POPs such as PCDD/F and PCB. In this context, not only the final determination of PFAS by LC/MS-MS methods is analytically very demanding, but also, irrespective of regional regulations, the sample preparation. The samples are cleaned up by solid phase extraction, eluted in a significantly smaller volume in methanol and then concentrated to dryness without loss and redissolved.

In order to be able to achieve correspondingly low limits of determination for the new limit specifications, a sufficiently large sample volume must be used. However, such large sample volumes represent a very high workload and time requirement for manual SPE, which is why automated processing of the samples is necessary. Another major challenge is posed by the ubiquitous perfluorinated and polyfluorinated substances found in the laboratory. The foreign input of PFAS analytes into the samples must be kept as low as possible in order to avoid false positive results. An undesirable, well known source of PFAS introduction into samples is the fluorocarbon materials such as PTFE used in commercially available laboratory equipment and materials. These release small amounts of PFAS during contact with the sample, resulting in significantly elevated background levels. Therefore, in the Freestyle SPE-PFAS system, which is used for automated SPE protocol processing, all fluorocarbon materials have been consistently minimized and replaced with polyethylene or polypropylene.

Both environmental samples, such as soil and water, and biota samples, such as animal tissue or food, can be purified fully automatically for PFAS analysis with the Freestyle SPE-PFAS system. When using sample volumes above 100 mL, the instrument system is also upgraded with the XANA water module. This then allows up to 24 samples of 1 L to be pumped from the rack via one SPE cartridge and significantly increases sample throughput by simultaneously processing up to 7 samples.

Figure 1 shows

the Freestyle PFAS-XANA system with the capacity of up to 24 1 L bottles (exemplified in the photo with glass bottles) with a D-EVA in use. To implement US EPA 537.1, samples were submitted in 250 mL PE bottles and the eluate was collected in 15 mL or 50 mL Falcontubes. Without further sample transfer of the eluate, the samples in these tubes were then transferred to the appropriate rotor of the D-EVA for gentle evaporation to dryness. For evaluation, the PFAS compounds of the existing DIN 38407-42 and the analytes of the updated US EPA 537.1 were processed on a freestyle PFAS XANAS system, providing evidence of all formal requirements for validation for US EPA 537.1. The results demonstrate that all PFAS compounds are recovered. This proves that no traces adhere to the system and, at the same time, no blank values are generated during processing on the robot. With regard to this, the PFAS background values of pure solvents were compared with the values of blank samples.

Fig.1 : The Freestyle PFAS XANA device system

in combination with a D-EVA from LCTech

Following SPE clean-up,

according to the method, the eluate of 8 mL methanol is brought to dryness by evaporation and redissolved for analysis in methanol/water 96:4 (v/v) according to

US EPA 537.1. Even this seemingly unproblematic step presents challenges to laboratories in PFAS analysis. Adhesion of PFAS to glass walls makes most of the equipment used for concentration unsuitable. Usually, the only remaining option is time-consuming and costly supervised blowdown with nitrogen, which should be avoided due to unintentional aerosol formation.

LCTech provides an automated solution in a D-EVA, which can hold the SPE eluates in classic Falcontubes and still allow a controlled process. In general, the D-EVA counteracts losses through its concept, as it uses infrared light for heating, lowers the boiling temperature especially with low pressures and prevents aerosol formation through rotation. However, since neutral PFAS in particular tend to be lost when concentrating beyond the dry point, it is necessary to ensure that the protocol is terminated in a controlled manner in good time. For this purpose, the D-EVA has a special sensor in a reference vessel, which reliably detects the dryness reached and stops the process. For this purpose, in-house protocols with the optimum speeds and the adapted termination temperature have been developed. When the target point is reached, the centrifuge chamber is ventilated and the infrared light used for temperature control is switched off, so that no further direct heating power is subsequently applied to the sample vessels. The so-called memory effect, known from heating blocks and water baths, is thus avoided. In this way, even the neutral PFAS can be concentrated very quickly and gently and measured with comparably high recoveries as after the cost- and time-intensive nitrogen blow-off.

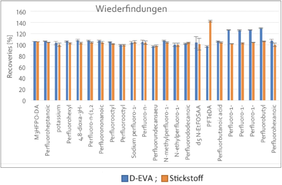

The graph in Figure 2 shows the recoveries of various PFAS relative to US EPA 537.1. 8 mL of methanol were doped and evaporated at the medium calibration level. This compares the method blowdown under N2 in a water bath to the evaporation method "methanol" in the D-EVA. The evaporated tubes are redissolved in methanol/water 95/4 plus internal standard and measured by HPLC-MS/MS.

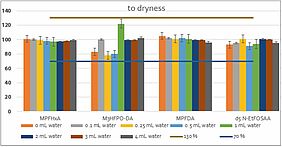

With exact application of US EPA 537.1, a certain residual water content in the eluate can sometimes not be avoided, which represents a further challenge for the concentration for drying. However, even samples with a water content of up to 25 % could be gently dried using the D-EVA.

Fig. 2: Comparison of recovery rates

In the experiment,

8 samples were doped with surrogate standard solution, with a concentration in the middle calibration range, then added different amounts of water and made up to 8 mL with methanol; all samples were evaporated with the D-EVA program "Methanol",. Any sample that is nearly dry is considered ready. When all samples are almost dry, they are dissolved in methanol/water 96:4% (v/v), added with internal standard and analyzed by HPLC-MS/MS.

Due to the high sample throughput of the Freestyle-XANA, another main goal of the D-EVA application is to evaporate faster than the methodology recommended by US-EPA 537.1, without risking loss of analytes, while providing desired better signal intensity and without any personnel supervision. In the respective rotors, 23 samples in 15 mL or 10 samples in 50 mL Falcontubes can be used in parallel. The fast program evaporates the eluates to dryness within 11 minutes and the longer program, which is selected especially for water-contaminated samples, within 77 min. Thus, the two devices can be ideally combined in the laboratory and the workflow for a high sample throughput can be realized.

CONCLUSION

Die analytischen Ziele der angewandten Methode wurden mit guten Wiederfindungen und sehr geringen Standardabweichungen ohne Kreuzkontamination erreicht, was auf die zuverlässige und robuste Automatisierung zurückzuführen ist. Gleichermaßen wurden auch die analytischen Ziele der DIN-Methode aufgrund der Automatisierung mit hoher Selektivität, Richtigkeit und Präzision erfüllt. Durch den Einsatz der automatisierten D-EVA-Vakuumzentrifuge, die eine unbeaufsichtigte parallele Aufkonzentrierung des gesammelten PFAS-Eluats direkt in dem Elutionsgefäß ermöglicht, in das es aus der SPE Säule eluiert wurde, ist eine schonende Aufkonzentrierung möglich, was eine besonders hohe Robustheit erzielt.

Fig. 3: Comparison of recoveries as a function of residual water

Falcontubes™ is a registered trademark of the company Falcon

|